A vibrant array of colours decorates the exterior walls of an industrial-looking building. Pink and purple street art plaster one side, with turquoise and lime green artworks displaying flora and fauna occupying the other. Housed in Florence, Italy, and spanning an area of over 37,000 square metres, Gucci ArtLab is where a certain sort of magic happens. Located near the headquarters of the company in Casellina, ArtLab has been active since 2018 and currently boasts a staff of over 950. A hub for in-house prototyping and sampling new products, it’s a centre for experimentation.

ArtLab features an artisan school with various programmes, each providing unique training experiences. This includes the craftsmanship school, factory school and technical academy. These courses are taught by a pool of staff who consists of world-class artisans, managers who run day-to-day operations as well as retired former colleagues, all dedicated to educating the next generation on the unique savoir-faire and house codes of the brand.

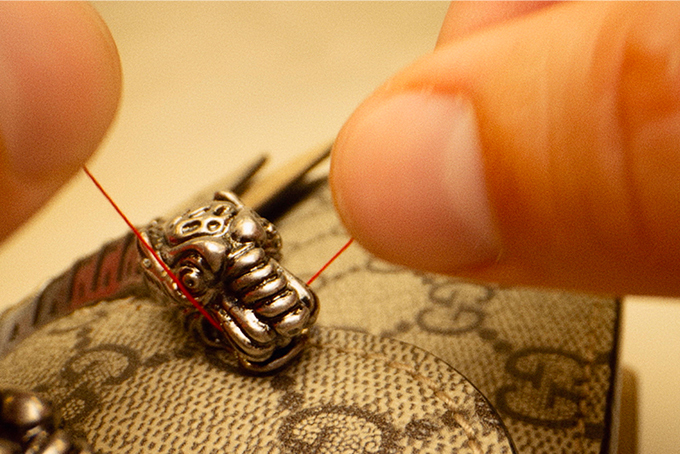

Antonella Centra, executive vice president general counsel of corporate affairs and sustainability at Gucci, credits part of the house’s success to the lab’s ability to transform an idea into reality. “ArtLab epitomises our desire to connect dots and create a collaborative ecosystem. It is an incredible place where designers enter with a dream and leave with a physical product. ArtLab’s mission is to meld art and industrial craftsmanship together to generate a unique combination capable of nurturing our designers and letting them unfold their creativity through innovative products.”

“ArtLab epitomises our desire to connect dots and create a collaborative ecosystem.”

So how exactly has Gucci achieved this? To date, ArtLab is renowned for the meticulous yet environmentally conscious processes used during manufacturing. Introduced in 2018, ‘scrap-less leather’, an innovative solution used to reduce leather wastage, was implemented. The programme has seen tremendous success, with 13 tanneries participating and over450 tons of leather scraps reduced to date.

Another pillar that has proved successful is Gucci Up, also launched in 2018. Introduced as a way to give life to scrap materials post-manufacturing(such as leather and textile leftovers), the programme has committed upcycled or discontinued fabrics and leathers to social cooperatives. This has simultaneously created new opportunities for women and marginalised socioeconomic groups.

Innovative products developed from research and development at ArtLab have helped reduce Gucci’s plastic footprint, such as the Gucci Circular Lines collection that features over 70 products all made of recycled, regenerated, organic and sustainably sourced materials. The main fabric and lining are made in Econyl, are generated nylon. Another example of the work done at the lab would be Demetria, an animal-free material that’s part of Gucci’sOff The Grid luggage collection. Demetria combines quality, softness and durability with an eco-friendly ethos. Furthermore, there are no impediments to scalability or limitations on volume, rarely seen in the majority of new materials produced.

The brand has also made changes to its packaging for retail and e-commerce, introducing green packaging made from paper and cardboard from responsibly managed sources. Previous freight packaging fillers have been replaced with reusable tote bags and adaptable freight packaging.

All these changes, however, have only enhanced what matters to the brand, which Centra perfectly describes: “The features inherent to Gucci’s products are quality, durability, aesthetics: our products are made to last, to be passed on from generation to generation.”

For more stories like this, subscribe to the print edition of Vogue Singapore.